Địa chỉ: Tầng 7, Căn số 32V5A, KĐT Văn Phú, phường Phú La, quận Hà Đông, TP. Hà Nội

Thời gian làm việc: Từ 8h - 17h từ Thứ 2 đến Thứ 6. Sáng thứ 7 từ 8h-12h, nghỉ Chủ Nhật

Địa chỉ: 228/55, Thống Nhất, P. 10, Q. Gò Vấp, TP. HCM

Thời gian làm việc: Từ 8h - 17h từ Thứ 2 đến Thứ 6. Sáng thứ 7 từ 8h-12h, nghỉ Chủ Nhật

| Hình | Mã hàng | Mô tả | Giá bán (vnđ) | Số lượng |

|---|---|---|---|---|

| HA4R8RA1000R022HAR050IM | 7104182 | Liên hệ | |

| HA4R8RA1600R032HAR400IM | 7104199 | Liên hệ | |

| HA4R8RA2500R045HAR300IM | 7104213 | Liên hệ | |

| HA4R8RA2500R045HAR250IM | 7104212 | Liên hệ | |

| HA4R8RA2500R045HAR200IM | 7104211 | Liên hệ | |

| HA4R8RA2500R045HAR100IM | 7104210 | Liên hệ | |

| HA4R8RA2500R045HAR050IM | 7104209 | Liên hệ | |

| HA4R8RA2000R038HAR600IM | 7104207 | Liên hệ | |

| HA4R8RA2000R038HAR400IM | 7104206 | Liên hệ | |

| HA4R8RA2000R038HAR300IM | 7104205 | Liên hệ | |

| HA4R8RA2000R038HAR250IM | 7104204 | Liên hệ | |

| HA4R8RA2000R038HAR200IM | 7104203 | Liên hệ | |

| HA4R8RA2000R038HAR100IM | 7104202 | Liên hệ | |

| HA4R8RA2000R038HAR050IM | 7104201 | Liên hệ | |

| HA4R8RA1600R032HAR300IM | 7104198 | Liên hệ | |

| HA4R8RA1000R022HAR100IM | 7104183 | Liên hệ | |

| HA4R8RA1600R032HAR250IM | 7104197 | Liên hệ | |

| HA4R8RA1600R032HAR200IM | 7104196 | Liên hệ | |

| HA4R8RA1600R032HAR100IM | 7104195 | Liên hệ | |

| HA4R8RA1600R032HAR050IM | 7104194 | Liên hệ | |

| HA4R8RA1200R026HAR300IM | 7104192 | Liên hệ | |

| HA4R8RA1200R026HAR250IM | 7104191 | Liên hệ | |

| HA4R8RA1200R026HAR200IM | 7104190 | Liên hệ | |

| HA4R8RA1200R026HAR100IM | 7104189 | Liên hệ | |

| HA4R8RA1200R026HAR050IM | 7104188 | Liên hệ | |

| HA4R8RA1000R022HAR300IM | 7104186 | Liên hệ | |

| HA4R8RA1000R022HAR250IM | 7104185 | Liên hệ | |

| HA4R8RA1000R022HAR200IM | 7104184 | Liên hệ | |

| HA4R8RA2500R045HAR400IM | 7104214 | Liên hệ | |

Dụng cụ đa năng: vừa phay thô vừa phay hoàn thiện, giảm số lần setup cần thiết.

Thiết kế lõi & me cắt độc quyền: khoảng cách tối ưu giúp hình thành phoi hoàn hảo, tăng độ cứng và ổn định dụng cụ.

Hiệu suất cao trên vật liệu khó: đặc biệt phát triển cho titan, hợp kim chịu nhiệt và thép không gỉ.

Hỗ trợ đa dạng phương pháp gia công: Trochoidal Milling, Helical Milling, Ramping, Side Milling / Shoulder Milling, Pocketing.

TechnicalInfo

| Angle of engagement (phi°) relative to cutting width (Ae) |  | |||||||||

| ae | 2% | 5% | 7.50% | 10% | 15% | 20% | 30% | 40% | 50% | 100% |

| phi - angle of engagement | 16.26 | 25.84 | 31.79 | 36.87 | 45.57 | 53.13 | 66.42 | 78.46 | 90 | 180 |

Application Data

| Adjustment factors for speed (Vc) and feed (Fz) • METRIC | |||||||

| Maximum cutting width (Ae) for given cutting depth (Ap) | |||||||

| Ap | ≤.125 x D1 | >.125xD1 ≤ .5xD1 | >.5xD1 ≤ 1xD1 | >1xD1 ≤ 2xD1 | >2xD1 ≤ 3xD1 | >3xD1 ≤ 4xD1 | >4 x D1 |

| Max Ae | 100% x D1 | 50% x D1 x KAp | 40% x D1 x KAp | 30% x D1 x KAp | 20% x D1 x KAp | 15% x D1 x KAp | 10% x D1 x KAp |

| Note: KAp value is given on the Speed and Feed table, according to the type of workpiece material selected. | |||||||

| Adjustment factors for speed (Vc) and feed (Fz) • METRIC | ||||||||||

| Ae/D1 | ≤2% | >2% ≤ 5% | >5 ≤ 7.5% | >7.5% ≤ 10% | >10% ≤ 15% | >15% ≤ 20% | >20% ≤ 30% | >30% ≤ 40% | >40% ≤ 50% | >50% ≤ 100% |

| Kv | 3 | 2.5 | 1.9 | 1.4 | 1.35 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| KFz | 3.28 | 2.3 | 1.95 | 1.7 | 1.5 | 1.25 | 1.09 | 1.02 | 1 | 1 |

| Note: Identify the radial engagement per percentage of the tool diameter (Ae/D1). That column will give you the factor to multiply the Base SMF and Base IPT on the Speed and Feed original table Kv = Factor to multiply the Speed by KFz = Factor to multiply the Feed by | ||||||||||

| To calculate application specific cutting data, please use KAp, Kv, and Kfz from tables above for adaption of cutting speeds and feeds respectively: Maximum Ae=(Ap1Max/D1) * KAp * D1 Vc new = Vc * Kv IPT new = IPT * KFz | Sample Calculation Material: S4 D1: 25 mm Ap: 2xD1 Max Ae: 30% x KAp x D1 --- 30% * 0.7 * D1 = 21%xD1 SFM: Base x Kv --- 45 * 1.2 = 54 IPT: Base x KFz --- 0.081 * 1.09 = 0.088 | Final cutting data recommendation: Max Ae = 0.3 * 0.7 * 25 = 5.25 mm Vc new = 45 * 1.2 = 54 m/min IPT new = 0.081 * 1.09 = 0.088 mm/th | ||||||||

| Table for Feed and Speed Calculation with Adjustment Factor • METRIC | ||||||||

| Side Milling (A) | KCSM15A | Recommended feed per tooth (fz=mm/th) for side milling | |||||

| Material Group | Max Ae Factor (KAp) | Base Cutting Speed Vc (m/min) | 10 | 12 | 16 | 20 | 25 | |

| P | 3 | 1 | 130 | 0.049 | 0.055 | 0.067 | 0.080 | 0.095 |

| 4 | 1 | 100 | 0.044 | 0.049 | 0.059 | 0.069 | 0.081 | |

| 5 | 0.8 | 65 | 0.038 | 0.043 | 0.053 | 0.063 | 0.076 | |

| 6 | 0.7 | 50 | 0.032 | 0.036 | 0.043 | 0.050 | 0.060 | |

| M | 1 | 1 | 80 | 0.049 | 0.055 | 0.067 | 0.080 | 0.095 |

| 2 | 0.8 | 60 | 0.038 | 0.043 | 0.053 | 0.063 | 0.076 | |

| 3 | 0.8 | 60 | 0.032 | 0.036 | 0.043 | 0.050 | 0.060 | |

| S | 1 | 0.5 | 50 | 0.049 | 0.055 | 0.067 | 0.080 | 0.095 |

| 2 | 0.5 | 30 | 0.038 | 0.043 | 0.053 | 0.063 | 0.076 | |

| 3 | 0.5 | 25 | 0.026 | 0.030 | 0.036 | 0.043 | 0.051 | |

| 4 | 0.7 | 45 | 0.041 | 0.051 | 0.061 | 0.069 | 0.081 | |

| H | 1 | 0.8 | 80 | 0.044 | 0.049 | 0.059 | 0.069 | 0.081 |

| 2 | 0.5 | 70 | 0.037 | 0.041 | 0.050 | 0.059 | 0.070 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on 12mm diameter. Maximum ramp angle is 2°. Tools with chip splitters can be used as finishers. | ||||||||

| Adjustment factors for speed (Vc) and feed (Fz) • INCH | ||||||||||

| Ae/D1 | ≤2% | >2% ≤ 5% | >5 ≤ 7.5% | >7.5% ≤ 10% | >10% ≤ 15% | >15% ≤ 20% | >20% ≤ 30% | >30% ≤ 40% | >40% ≤ 50% | >50% ≤ 100% |

| Kv | 3 | 2.5 | 1.9 | 1.4 | 1.35 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| KFz | 3.28 | 2.3 | 1.95 | 1.7 | 1.5 | 1.25 | 1.09 | 1.02 | 1 | 1 |

| Note: Identify the radial engagement per percentage of the tool diameter (Ae/D1). That column will give you the factor to multiply the Base SMF and Base IPT on the Speed and Feed original table Kv = Factor to multiply the Speed by KFz = Factor to multiply the Feed by | ||||||||||

| To calculate application specific cutting data, please use KAp, Kv, and Kfz from tables above for adaption of cutting speeds and feeds respectively: Maximum Ae=(Ap1Max/D1) * KAp * D1 Vc new = Vc * Kv IPT new = IPT * KFz | Sample Calculation Material: S4 D1: 25 mm Ap: 2xD1 Max Ae: 30% x KAp x D1 --- 30% * 0.7 * D1 = 21%xD1 SFM: Base x Kv --- 45 * 1.2 = 54 IPT: Base x KFz --- 0.081 * 1.09 = 0.088 | Final cutting data recommendation: Max Ae = 0.3 * 0.7 * 25 = 5.25 mm Vc new = 45 * 1.2 = 54 m/min IPT new = 0.081 * 1.09 = 0.088 mm/th | ||||||||

| Table for Feed and Speed Calculation with Adjustment Factor • INCH | |||||||||

| Side Milling (A) | KCSM15A | Recommended feed per tooth (fz=IPT) for side milling | ||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||

| Material Group | Max Ae Factor (KAp) | Base Cutting Speed Vc (SFM) | dec. | 0.375 | 0.500 | 0.625 | 0.750 | 1 | |

| P | 3 | 1 | 420 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.003 | 0.0037 |

| 4 | 1 | 320 | IPT | 0.0016 | 0.0021 | 0.0024 | 0.0026 | 0.0031 | |

| 5 | 0.8 | 210 | IPT | 0.0014 | 0.0018 | 0.0022 | 0.0024 | 0.0029 | |

| 6 | 0.7 | 160 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0019 | 0.0022 | |

| M | 1 | 1 | 275 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.003 | 0.0037 |

| 2 | 0.8 | 200 | IPT | 0.0014 | 0.0018 | 0.0022 | 0.0024 | 0.0029 | |

| 3 | 0.8 | 200 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0019 | 0.0022 | |

| S | 1 | 0.5 | 160 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.003 | 0.0037 |

| 2 | 0.5 | 100 | IPT | 0.0014 | 0.0018 | 0.0022 | 0.0024 | 0.0029 | |

| 3 | 0.5 | 80 | IPT | 0.001 | 0.0013 | 0.0014 | 0.0016 | 0.002 | |

| 4 | 0.7 | 160 | IPT | 0.0016 | 0.002 | 0.0024 | 0.0027 | 0.0032 | |

| H | 1 | 0.8 | 260 | IPT | 0.0016 | 0.0021 | 0.0024 | 0.0026 | 0.0031 |

| 2 | 0.5 | 230 | IPT | 0.0014 | 0.0018 | 0.002 | 0.0022 | 0.0026 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on 12mm diameter. Maximum ramp angle is 2°. Tools with chip splitters can be used as finishers. | |||||||||

| Adjustment factors for speed (Vc) and feed (Fz) • INCH | |||||||

| Maximum cutting width (Ae) for given cutting depth (Ap) | |||||||

| Ap | ≤.125 x D1 | >.125xD1 ≤ .5xD1 | >.5xD1 ≤ 1xD1 | >1xD1 ≤ 2xD1 | >2xD1 ≤ 3xD1 | >3xD1 ≤ 4xD1 | >4 x D1 |

| Max Ae | 100% x D1 | 50% x D1 x KAp | 40% x D1 x KAp | 30% x D1 x KAp | 20% x D1 x KAp | 15% x D1 x KAp | 10% x D1 x KAp |

| Note: KAp value is given on the Speed and Feed table, according to the type of workpiece material selected. | |||||||

THIẾT BỊ CƠ KHÍ ĐỨC PHONG

Hà Nội: Tầng 7, Căn số 32V5A, KĐT Văn Phú, phường Phú La, quận Hà Đông, TP. Hà Nội (Xem địa chỉ map)

Hotline: 0985779287 (Zalo)

website: https://ducphongstore.vn/

Mail: Info@ducphong.vn

Hỗ trợ 24/7

Chi nhánh Hồ Chí Minh: 228/55, Thống Nhất, P. 10, Q. Gò Vấp, TP. HCM

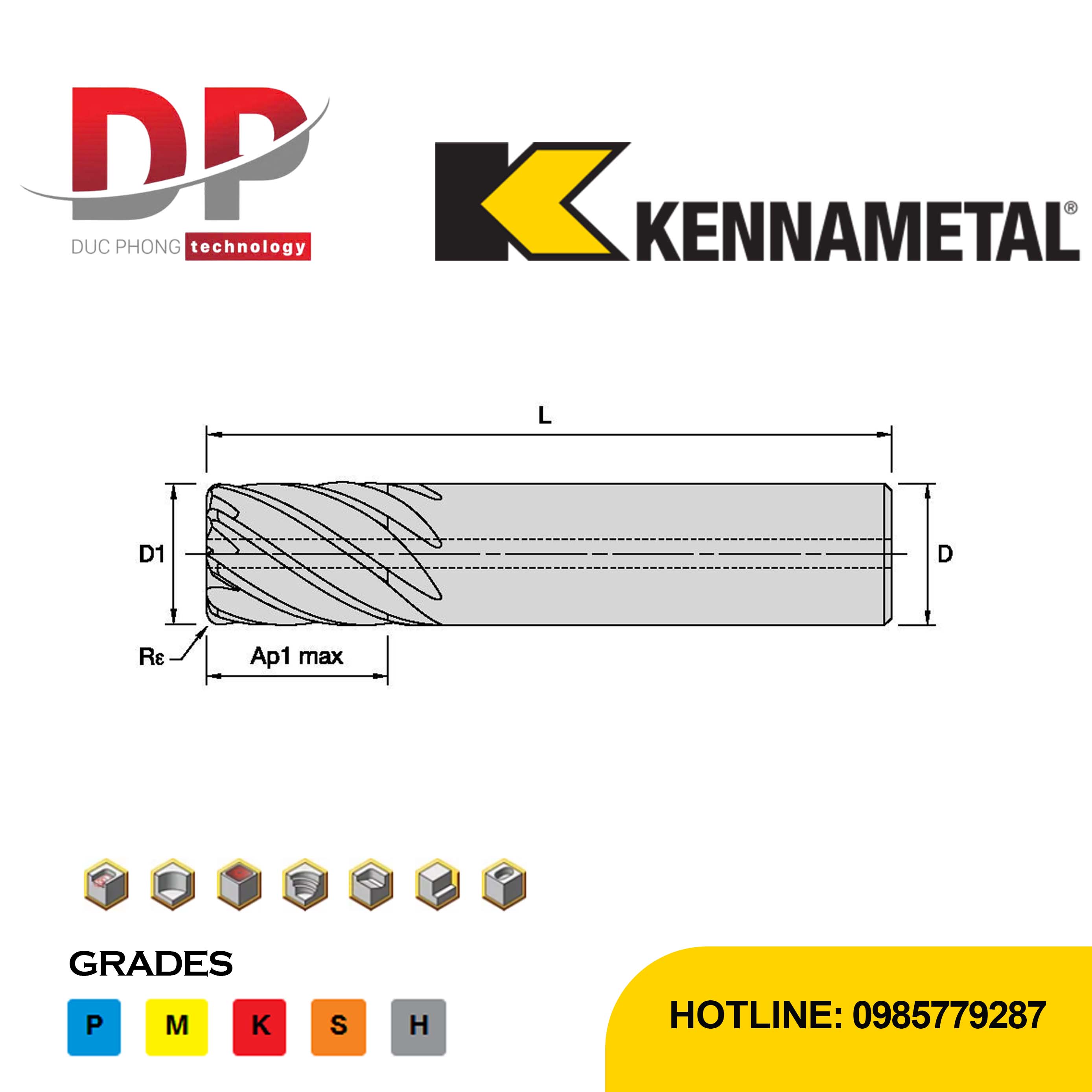

Đánh giá Dao phay ngón carbide Kennametal HARVI™ IV, 8 me, làm mát trong, cán trơn, hệ mét

Bạn chưa đánh giá sao cho sản phẩm này

Đánh giá ngayHotline

0985779287

Info@ducphong.vn

Hotline

098 5779287 (Zalo)

098 5779287 (Zalo)

vananh.ng@ducphong.vn

Info@ducphong.vn

Hotline: 098 5779287 (Zalo)